Use AU500 Hardener/Activator For this product 5:1 Order Code AU500-100

Use RS605 Reducer/Thinner with the product @ 10%-25% Order code RS605-500

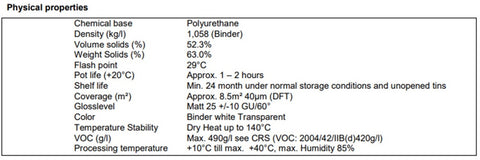

Product Description: TB512 PU Topcoat Binder DTM Matt is a two component polyurethane topcoat (direct to metal), with the exception of aluminum & galvanized steel substrates.

This topcoat contains special pigments which enhances corrosion protection) with a semi gloss finish, 25 +/-10 GU/60° this is dependent on color and spray technique. For a higher level of anticorrosion performance, we recommend to use of an epoxy primer first. TB512 is specifically developed for light

Industrial use, application properties enable fast operation with good force dry and air-dry capabilities. The standard mixing ratio is 80% Binder, 20% colour toner or optional 70% Binder, 30% colour toner for low opacity colours.

All colour toners are chromate and lead free, also providing good UV protection. Air drying is recommended, force-drying will result in a higher gloss finish. Selection of hardener, reducer & color, can affect viscosity, flash-off time and thickness, this will also have an influence on the end gloss result too.

Substrates: Iron, steel, stainless steel (blasted) cast iron, primed galvanized steel, primed aluminum, glass fiber reinforced plastics (GRP). Primer options: FP400/401 or FP440 Epoxy Primer, FP402 Epoxy Primer Zinc rich, FP500/PB500 PU Primer DTM, FP510 HS Surfacer, FP620 1K Wash primer and FP600 Plastic Primer (refer to FP600 TDS for list of recommended plastic substrates).

Other: Solvent resistant existing ridged paint finishes, cleaned/sanded. Iron/steel: Abrasive shot blasting is recommended or dry sanding P80 – P180 with a 5mm orbital sander.

Aluminum: Because of the wide number of aluminum types we recommend to use primers as described above for the best adhesion and corrosion protection on aluminum before applying this topcoat.

For proper preparation of the aluminum substrate follow the steps as described in TI Aluminum. Sanding aluminum recommendations: P80 – P180* Galvanized: For proper preparation of the Zinc substrate follow the steps as described in TI Galvanized steel (Sweep blasting is recommended).

Paint finishes: P180-P320 (check and change abrasive paper regularly to ensure correct sanding grade scratches (Sweep blasting is recommended). Stainless steel: Blasting followed by a VIM Epoxy Primer. Paint finishes: P280 – P360 (Please, check and change abrasive paper regularly as required). Cleaning:

Surface must be dry and free from any contamination, eg, oil, grease, release agents and incorrectly used degreasers (if degreasers are used incorrectly they may leave a residue)

Use VIM AD690 Solvent degreaser for all substrates and paint finishes as per the Technical Data Sheets. Surface Preparation:

Abrasive blast to EN ISO 12944, Part 4 (ISO Sa 2.5) with a uniform blast profile of 20 to 50µm For more detailed information go-to TI-Substrate (TI-G-09 in chapter 3 Purple Box) and

Pretreatment or website www.valsparindustrialmix.com. *In light industrial and CT sectors, many different types of aluminium’s are used in manufacture and fabrication. Because of this, good sanding and cleaning is essential to create a sound coating process. Please contact your local technical adviser if unsure of the correct process and or materials.